Linya ng Produksyon ng Carbon Fiber Precursor

Paglalarawan

Ang paraan ng produksyon ng carbon fiber precursor na gumagamit ng Dimethyl Sulfoxide(DMSO) bilang solvent, Acrylonitrile(AN) bilang unang monomer, Itaconic Acid bilang pangalawang monomer, AIBN bilang initiator na magkaroon ng binary copolymerization, at ang dry-jet wet spinning ay ang nangungunang pagpipilian na napagkasunduan sa mga eksperto sa carbon fiber.

Tech Specs:

| Hindi. | item | Yunit | Mga pagtutukoy | Remarks |

| 1 | Linear Density | dtex | 1.15 | |

| 2 | lakas ng makunat | CN/dtex | ≥4.0 | |

| 3 | Pagpahaba | % | 12±2 | |

| 4 | Nilalaman ng Dimethyl Sulfoxide(DMSO). | % | <0.03 | |

| 5 | Nilalaman ng Langis | % | 0.5-0.1 | |

| 6 | End Breakage Rate | % | <3 | |

| 7 | Muling Halumigmig | % | ≤1 | |

| 8 | Hitsura | Walang Tila Sirang Filament |

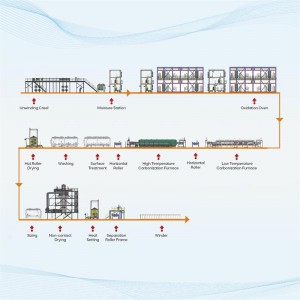

Proseso:

Paghahanda ng Raw Material —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Storage —→ Defoam —→ Spinning —→ spin bath (Pangunahin) —→ spin bath paliguan (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Drying —→ Steam Stretching —→ Heat Setting —→ Antistatic Treatment —→ Precursor Winding

| Hindi. | item | Yunit | Mga pagtutukoy | Remarks |

| 1 | Linear Density | dtex | 1.15 | |

| 2 | lakas ng makunat | CN/dtex | ≥4.0 | |

| 3 | Pagpahaba | % | 12±2 | |

| 4 | Nilalaman ng Dimethyl Sulfoxide(DMSO). | % | <0.03 | |

| 5 | Nilalaman ng Langis | % | 0.5-0.1 | |

| 6 | End Breakage Rate | % | <3 | |

| 7 | Muling Halumigmig | % | ≤1 | |

| 8 | Hitsura | Walang Tila Sirang Filament |

Raw Paghahanda ng Materyal —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Storage —→ Defoam —→ Spinning —→ spin bath (Pangunahin) —→ spin bath paliguan (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Drying —→ Steam Stretching —→ Heat Setting —→ Antistatic Treatment —→ Precursor Winding